Operation and Maintenence Training

Certified Operations & Maintenence Engineer

CurriculumWhy to choose usBest Places to Work

The primary and overall objective of this course is to give a hands-on experience of Operations & Maintenance

- Fundamentals

- SCOPE of facility maintenance Manager, engineer, and maintenance Technicians.

- Routine maintenance.

- Breakdown maintenance.

- Preventive maintenance

- Predictive maintenance.

- Read and Understanding O & M manuals.

- Read and Understanding EQPT and OEM manuals.

- EQPT Warranty/Guaranty claiming procedure.

- Spare parts procurement, storing and inventory procedures.

- Reading and Understanding DWGs, Schematics and Symbols

- Basic formulae and UNIT conversion.

- Measurement Techniques.

- Basic Hand Tools

- Portable Power Tools

- Basics of Health and Safety (H&S) RULES.

- Troubleshooting Techniques and Skills

- Basic Electricity and Electronics.

- Read and Understanding Electrical SLD and different components.

- Different kinds of circuit breakers, MCB, MCCB, ACB, SF6, and their applications.

- Batteries and DC Circuits

- Transformers and AC Circuits

- Electrical Measuring Instruments

- Electrical Safety and Protection.

- Basics of Relay, contactors, over load accessories, and other accessories.

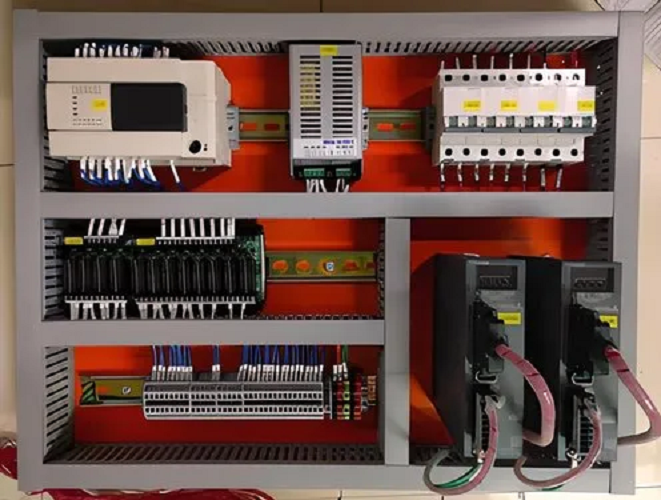

- Basics of Electrical panel boards, MDB, SMDB,DB.

- Relay logics interlocks,

- MCC CKTs, DOL, STAR-DELTA, Soft starters and VFD controllers.

- Single-Phase Motors

- Three-Phase Systems

- AC Control Equipment

- Electrical Troubleshooting

- Electrical Safety in the Workplace Understanding NFPA 70E®.

- UPS system and Maintenance and trouble shooting.

- Maintaining electrical system LOG book.

- Semiconductors

- Power Supplies

- Amplifiers

- Oscillators

- Digital Logic Systems

- Basic Mechanics

- Lubricants and Lubrication

- Power Transmission Equipment

- Bearings

- Pumps

- Piping Systems

- Basic Pneumatics

- Pneumatic Troubleshooting

- Mechanical Drive Maintenance

- Mechanical and Fluid Drive Systems

- Bearing and Shaft Seal Maintenance

- Pump Installation and Maintenance

- Maintenance Pipefitting

- Tubing & Hose System Maintenance

- Valve Maintenance/Piping System Protection

- The Refrigeration Cycle

- Refrigerants & Refrigerant Oils

- Compressors, CHILLER systems, CHW-Pumps, Primary & SEC pumps.

- Evaporators and Metering Devices

- Condensers and Cooling Towers

- Piping

- Air-Handling Systems, FCUs, EF, SEF, SAF and their application.

- System Troubleshooting

- Absorption Chillers

- Heat Pumps

- Heating System Basics

- Heating System Equipment

- Energy Conservation Basics

- Energy Losses in Buildings

- Heating/Cooling System Efficiency

- Mechanical Energy Conservation

- Electrical Energy Conservation

- Cleaning Chemicals

- Floors and Floor Care Equipment

- Maintaining Floors and Other Surfaces

- Rest Room Care

- Carpet and Upholstery Care

- Chemical Hazards: OSHA’s Hazard Communication Standard

- Machine Shop Practice

- Bulk-Handling Conveyors

- How Power Plants Work

- Generating Steam in the Power Plant

- Using Steam in the Power Plant

- Waste-to-Energy Fundamentals

- Pressure Measurement

- Flow Measurement

- Level Measurement

- Programmable Logic Controllers

- Industrial Rigging

- Equipment Installation

- Introduction to Water Technology

- Wastewater Treatment Processes

- Blueprint Reading for Welders

- Welding Principles

- Oxyfuel Operations

- Arc Welding Operations

- FA System basics.

- Different types of extinguishers their application and handling.

- FACP, smoke & heat detectors, call points, strobe, siren. F& S dampers.

- Concept of FA Zone, fire escape routes, emergency escape-stairway.

- Concept of smoke management and fireman override system.

- Difference between fire detection, fire alarm, and firefighting system.

- Introduction to Different firefighting system, FM200, VESDA, Sprinkler system etc.

- Fire pumps, Jockey pumps, diesel pumps, fire water tanks, MIMIC.

- emergency electrical power system, ATS and their functions.

- Maintenance procedures for Fire pumps, Jockey pumps, diesel pumps, fire water tanks,

- Rolls and responsibility of FIREMAN and Maintenance engineers and Co-ordination.

- Rolls and responsibility of maintenance engineers during fire emergencies and during fire drill.

- Preventive and predictive and Routine maintenance and logging of various FA system equipment .

- Understanding FIRE / SMOKE system CAUSE and EFFECT matrices.

- BMS basics.

- Referring O&M Docs. equipment manual, I/O &BOM/BOQ.

- Operation schedules, work orders, different O& M forms.

- O&M Planning / Implementation Technics, Maintenance scheduling.

- Understanding System Flow Diagrams.

- Understanding The BMS riser drawings.

- Understanding DDC panel DWG,

- Maintenance spare parts procurement and logistics.

- Understanding Various BMS System field devices.

- Basics of Controller configuration DDC Programing / OWS

- Alarms, history trending .

- Alarm acknowledgement and work order procedure.

- BMS O&M Budgeting &Financial Aspects .

- Recourses allocation.

Electrical Systems

Electronics

Mechanical Systems

Mechanical Maintenance Applications

Air-Conditioning & Refrigeration Systems

Energy Conservation

Custodial Maintenance

Hazard Control

Machine Shop Practices

Material Handling Systems

GENARATORS &Power Plant Operations

Process Control Instrumentation

Programmable Logic Controllers

Rigging & Equipment Installation

Water/Wastewater Treatment

Welding

FIRE ALARM SYSTEM.

BUILDING MANAGEMENT SYSTEM. BMS

[table id=1 /]