HVAC (Heating, Ventilation & Air-Conditioning) Designing & Draughting

Post Graduate Diploma in HVAC Training

Course Description:

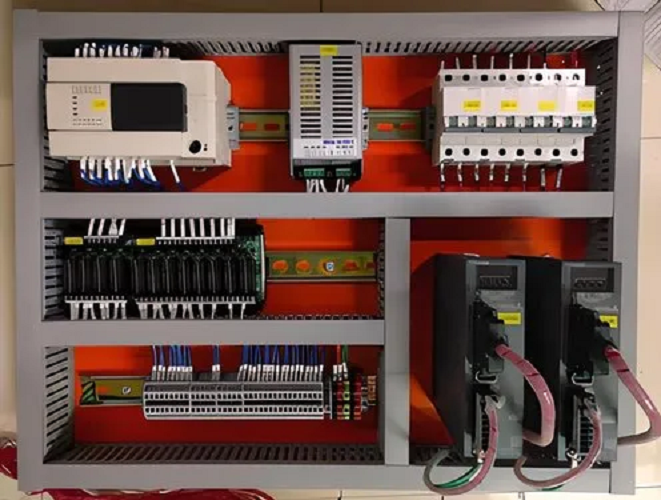

Today’s highly increasing competitiveness over the industry demands high quality and most consistent products with a competitive price. To address this challenge number of industries considering various new product designs and integrated manufacturing techniques in parallel with the use of automated devices.

Automation takes a step further mechanization that uses a particular machinery mechanism aided human operators for performing a task. Mechanization is the manual operation of a task using powered machinery that depends on human decision making.

One of the remarkable and influential moves for getting the solutions of above mentioned challenge is the industrial automation. Industrial Automation facilitates to increase the product quality, reliability and production rate while reducing production and design cost by adopting new, innovative and integrated technologies and services.

Course Objectives:

- Complete knowledge of HVAC Design & Drafting.

- Able to do Design, Calculation and Estimate.

- Able to Troubleshoot Hardware.

- Able to work in HVAC Manufacturing, Production, Commercial Buildings, Hospitals, Oil & Gas, Power Plant etc.

- Real-time Projects Execution.

The primary and overall objective of this course is to give a hands-on experience of HVAC Design & Drafting, Calculations, Estimation of the Project.

- Introduction to Building Construction (Civil & MEO Services) Introduction to Heating Ventilation and Air conditioning

Basics of Heat Transfer

- Modes of Heat Transfer in a building (Conduction, Convection and Radiation), Forms of Heat (Sensible & Latent Heat), Temperature TON of Refrigeration & Unit Conversion (Manually Conversion Software).Standards and codes used in HVAC

- Study on Psychrometric Charts (Manual and ASHRAE Analysis Software).Properties of Air (Altitude, DBT, WBT, %RH, DPT, Humidity Ratio & Enthalpy).

- Study on Refrigerants : Types of refrigerants, Evaporating & condensing properties of Refrigerants.

- Types of Refrigeration cycles & its Components: Vapor Absorption refrigeration System,Vapor Compression refrigeration system, Types of Compressors, Condenser, Expansion Valve & Evaporator Coil, Vulcan Lockring (Copper Pipe joining method).

- Types of Air Conditioning Systems : Non-Central AC, Package AC System, VRV/VRF System, Chilled Water System.

- Types Of Fans & its Application, Fan Laws

- Types of Pumps, Pump Laws, Pump in Series and ParallelHVAC DESIGN CALCULATIONS

- Cooling & Heating Load Calculation : General & E-20 manual calculation, Ventilation and Infiltration Load Calculation, Winter load calculation Ventilation System Designing, Fresh Air Handling Unit Designing as per ASHRAE 62.1., Restaurant/Residence kitchen ventilation system designing as per ASHRAE 90.1, Non Central and Central Toilet Exhaust Calculations as per ASHRAE 62.1., Car Parking Ventilation system Designing(Impulse & Induction Fan System, Design of Stairwell Pressurisation System, Design of Smoke Management System, Transformer Room and Generator Room ventilation requirements.Study on Air Distribution Systems (SMACNA & DW-142)

- Types of Ducts, Duct fittings, Dampers, Flexible ducts, Classification of Duct(Low, Medium & High pressure), Duct gauge selection, Comparision between different shapes of duct, Duct Fabrication, Insulation & Installation procedure, Vanes location & number of vanes required, Type of Duct Materials, Calculation of total sheet required for Duct Fabrication & estimating duct weight in kgs, Selection of Duct Gauges & thickness, Hanger Spacing, Hanger Road Diameter and Angle support Size, Types of Air Terminal Device, Selection and Sizing Of Air Terminal Device (Manually).Duct Designing methods (Manual Calculations)

- Equal friction method, Velocity reduction method, Static regain methodPipe Sizing methods

- Refrigerant Pipe sizing, Chilled water pipe sizing, Study on Chilled Water Systems, Types & Application of Chillers, AHU’s, FCU’s & FAHU’s, Chilled Water Pipe Sizing by ASHRAE standards, Types of Valves & Its Connection, Valve Authority, Open loop & Closed loop system, Primary and Secondary pump system, Common Header Pipe Sizing, Hydraulic Calculation for Pump Selection, Expansion Tank Sizing, Air Separator, Pump Cavitations, Pump Curves, NPSH Calculation for Pumps, Advance Psychrometric Analysis, Determine Mix Air Temperature, Calculate the Flow of Air, ESHF, Ton of Refrigeration, Design of CAV & VAV System

- Air Balancing System and Pressurization of Space.

- Desert Cooler Selection

- District Cooling System

- Cooling Tower Selection, Evaporation losses, Drift losses calculation, Pump Head Calculation

- Coil Selection

- ESP Calculation

- Variable Refrigerant Volume (VRV) System Designing

- Dehumidifier Selection (Silica gel & Desiccant DH)

- HRW-Heat Recovery System (Rotor Wheel, Heat Pipe, Run around coil & Plate Heat Exchanger)

- Estimation and Costing

- Cold Storage Designing

- Silencer- Sound Attenuator Designing

- BMS (Understanding Sequence of Operation for HVAC System

- Energy Conversation measures (ECM): Under Floor Air Distribution System (UFAD), Chilled Beam System, Radiant Cooling, Geothermal Cooling, Thermal Energy Storage System (TES) or ICE on Pipe System, Demand Control Ventilation (DCV), EAT-Earth Air Tunnel System, Cooling without Air-Conditioning & Passive Cooling System Desinging

- Green In HVAC system Designing-Energy Modeling Concept.

EQUIPMENT SELECTION

- Selection of cooling tower, Selection of Chillers, AHU and FCU classification and selection, Package unit selection DX unit selection, Selection of Dehumidifier, Pump Selection, Fan Selection.SOFTWARE DESIGNING

- Cooling and heating load calculation using Hourly Analysis Programme (HAP) & Elite Software, Calculation of duct sizes by McQuay Duct Sizer and Duct Checker Software, Calculation of Chilled Water pipe sizes by McQuay pipe sizer Software, Air terminal (Grills, Diffusers, Registers, LBG- Linear Bar Grills, SLSD-Supply Linear Slot Diffuser) selection by using BETA Programme, HVAC Equipment (Package AC, Chiller, AHU, FCU etc,) Selection by Zamil Software, VRV Equipment Selection by TOSHIBA Software.ESTIMATION AND COSTING OF PROJECT

- Understanding the tendering requirements, Quantity take off, Preparing Inquiry for Suppliers & Finalizing the suppliers, Final Billing & Quotations finalizationPROJECT PROCUREMENT

- Preparation of purchase orders, Quotation Evaluation SheetHVAC DRAFTING

- Representation of Concepts Design Drawing, Design Drawing & Shop Drawing, Preparation of Detail Shop Drawing of Air-Conditioning & Ventilation Ducts, Chilled Water Pipes & Duct Fittings-Elbows, TEE’s, WYE, Dampers- Volume Control Dampers (VCD), Splitter Damper(SD), Smoke Dampers, Fire Dampers(FD) etc. & Duct Support, Reservation of Duct Pipe Levels, Slope, flow direction, BOD’s, BOP’s, Typical detail of Chillers, AHU’s, FCU’s, Pumps, Valves- Isolating, Regulating, NRV, Strainer etc., Representation of Section Drawings.