4.5/5

- 4.5 ( 693 Reviews)

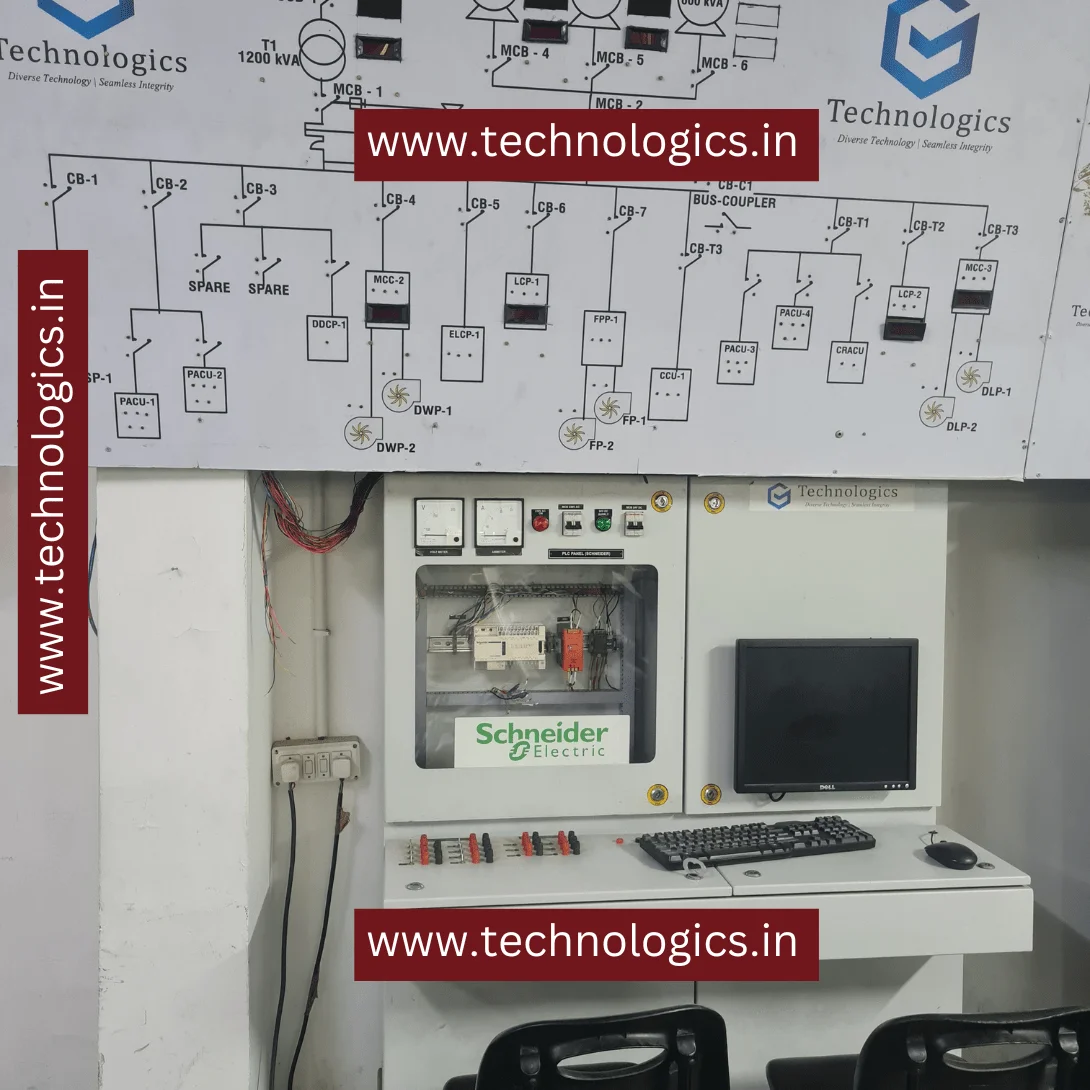

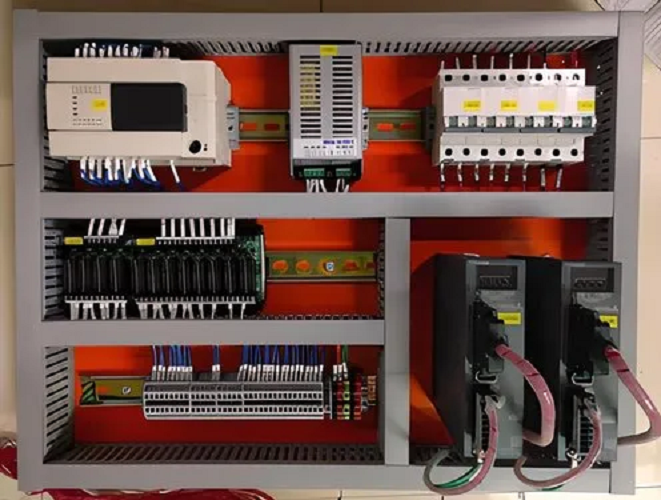

Hand’s On Siemens PLC SCADA Training in Programming, Wiring, Testing & Commissioning

- Genuine Placement

- 85k Enrolled

- All levels

- English

Training Overview

| PLC Training | Siemens S7-300. |

|---|---|

| SCADA Training | Wincc, TIA Portal. |

| HMI Training | KTP-700. |

| VFD Training | Micromaster. |

| DCS Training | PCS 7. |

| Servo & Stepper Motor Training | Panasonic Drives, Delta. |

| Energy Meter | Schnieder, Emeasure, Trinity. |

| Relay Logics | Logic Design and Wiring |

Syllabus - In Detail

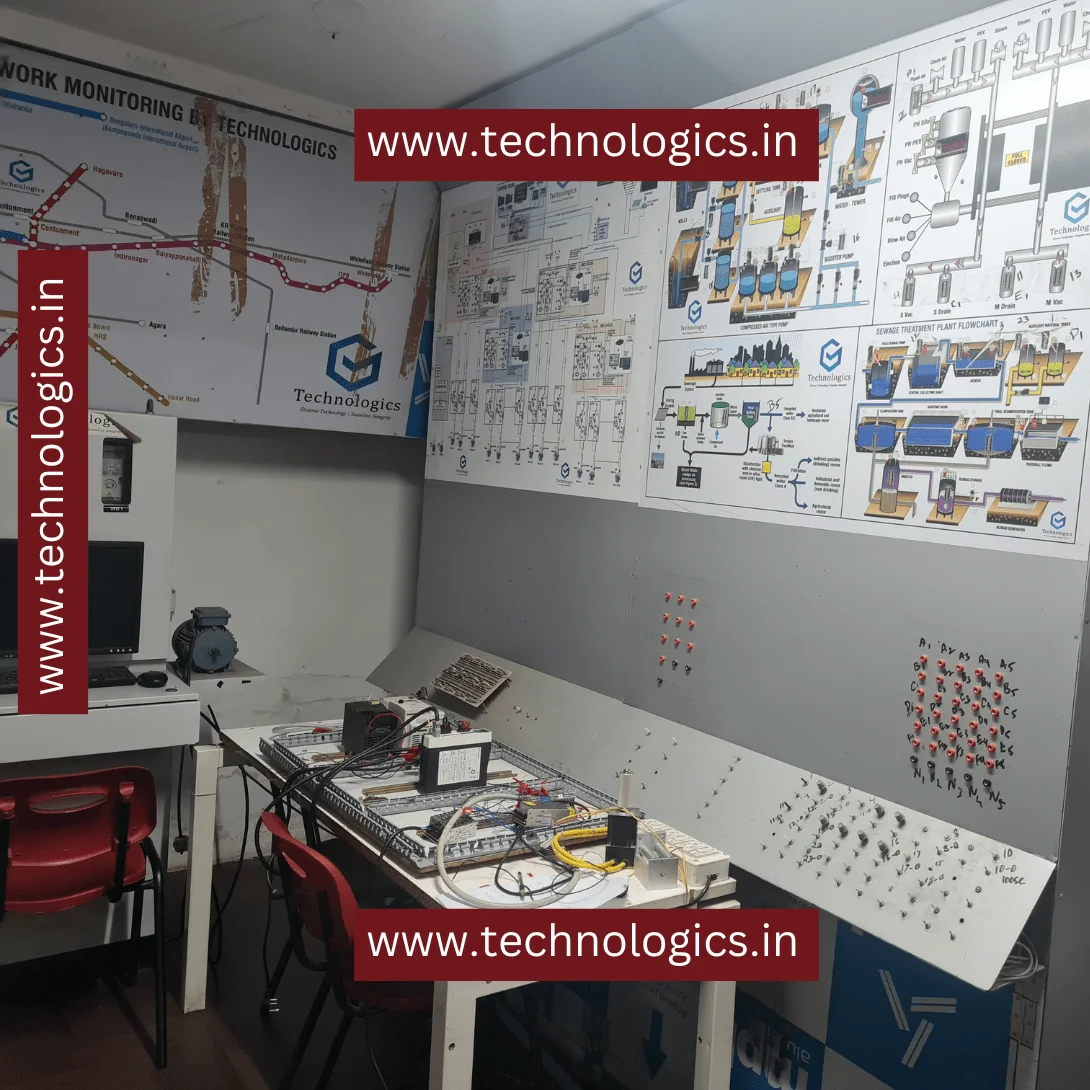

The primary and overall objective of this course is to give a hands-on experience of PLC, SCADA, VFD, HMI, DCS, Field Instruments.

- Introduction about industrial automation

- History of industrial automation, Need of automations in industries

- Example for industrial automation

- Automation control circuit and power circuit

- Field Instruments, Types and working of field devices

- Automation using relays and field devices

- Examples for relays and field devices & Logical functions done by relays and field devices

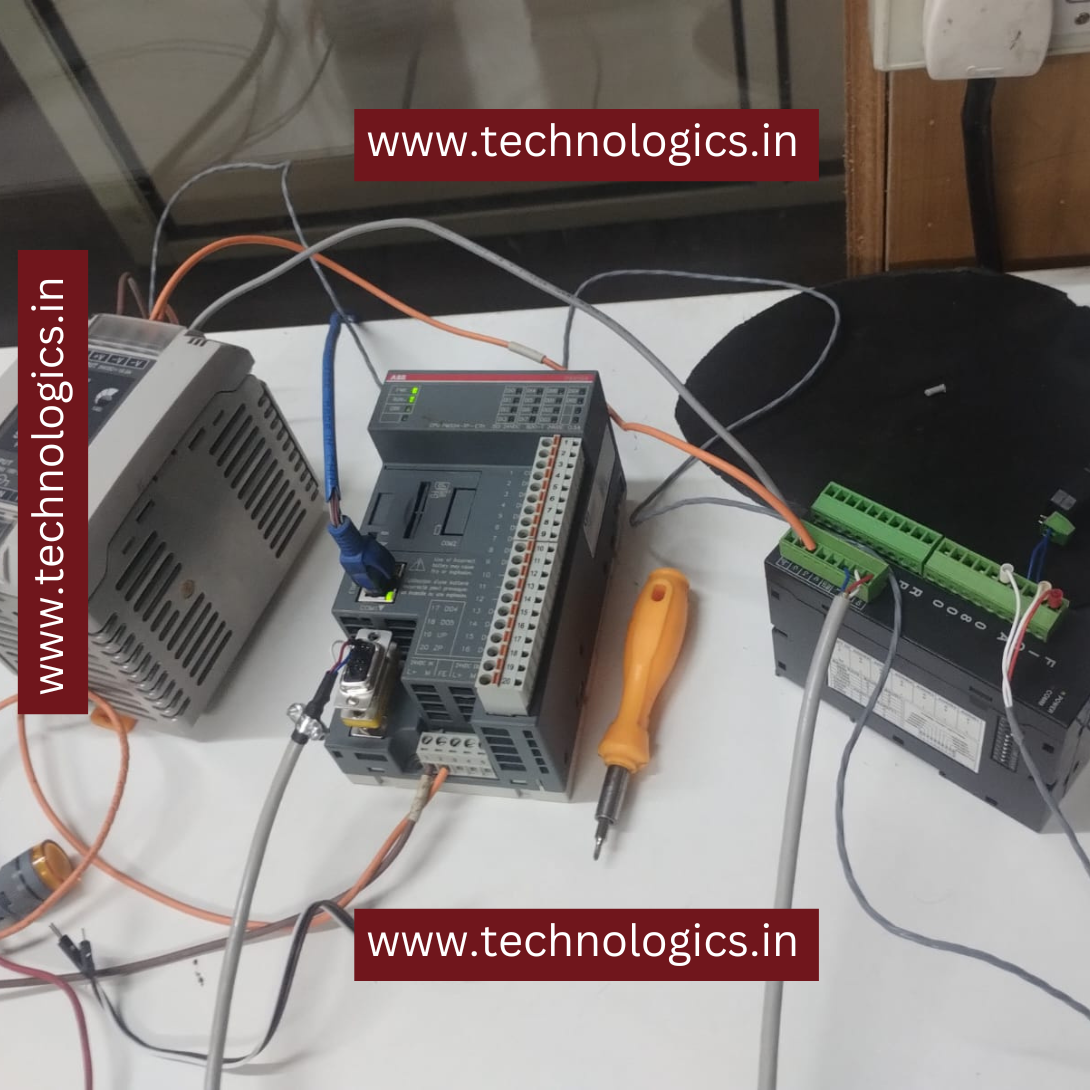

- Introduction about Programmable Logic Controller, History of PLC, Architecture of PLC

- CPU, IO Modules, Power Supply and Communications, Input and Output Devices, Need of PLC for Industrial Automation

- Types of PLC Models, Introduction about PLC Programming

- Types of Programming Languages, Introduction about PLC Programming software

- Ladder logic diagram, Structure of program, Procedure for creating ladder diagram, Logical function done by ladder program in software.

- Interfacing the field component to PLC, Sink and Source type wiring, Need of push button for industrial automation

- Importance of latching and unlatching concepts, Memory concept.

- Working with – All Major Brands of PLC

- Interlocking & Trip concept

- Types of interlocking, Need of interlocking

- Timers, Types of timers & Example Problem for automation using timers

- Need for counters & Types of counters – Example for automation using counters

- Jump and subroutine & Importance of loop instruction – Examples : Automation using Jump and Subroutine. – Upload and Download Program.

- Introduction, definition and history of Supervisory Control and Data Acquisition,

- Typical SCADA System Architecture, Communication Requirements,

- SCADA systems in operation and control of interconnected power system, Power System Automation, Petroleum Refining Process, Water Purification System, Chemical Plant

- Remote Terminal Unit (RTU), RTU Configuration, RTU Hardware Modules

- Project Creation in Display, Tags, Library, Run Time, Security, Working with Properties, Animation, Alarm Setup, Trend, Language Switching, Interfacing PLC to SCADA.

- Industrial Project Documents

- P&ID Diagrams & IO List Preparation

- VFD Selection, Functions of VFD Switches & Symbols,

- Operate motor using VFD Console switches.

- Parameterisation, Checking Load, rated Voltage & current

- Comissionining, No Load Test, Speed Modulation, ON/ OFF Command, Trip Status, PID Tuning

- Interfacing PLC To VFD, Real Time Interface to PLC SCADA

- Intro to HMI

- Designining In HMI- Diffrent Types of Operaters, Textual & Graphical

- Properties for Design, I/O Configuration, Wiring of HMI, Data Handling

- Configuration & Interfacing from PLC to PC

- DCS – Distributed Control System

- Architecture of DCS, Hardware Configuration , I/O Modules, Communication Module, Troubleshooting

- I/O Wirining, Programming, CPU IP Setting & Addressing, Node Addressing, Upload & Download Monitoring,

- SCADA Interfacing, Fault Detection, Operater Interface, Designing, OPC / ODBC

- Communication Protocol, Ethernet

- Projects, Assignments & Test

Absolutely loved the lash lift training!I wasn’t sure what to expect when registering for the training as an online course for embedded systems as I have only trained in college environment before. I personally called Fayaz sir and he made sure all my queries are cleared. I can honestly say that it has been fantastic. I felt that I had just as much information and help as any college course I have done … may be even more. The training material they provide is so easy to understand and I want to thanks Shabaz sir and Shrinivas sir for being so wonderful teachers I could ever wish for. I do not regret even for a second to be a part of TECHNOLOGICS.

First I would like to say thank you for giving these opportunity and special thanks to fayaz sir, shabaz sir and srinivas sir. They are going through our wrongs and make it correct .They give us all experienced what they know and make us experienced and becomes bold to crack the interview in simple. The class environment is good and enjoyable. Learning new things has great values , they are giving all for us to get dream job.

Good experience, The training was really good and great to have this training. I had excellent experience learning from R&D specialist trainers and extensive effort from them on live coding session.75% of training completion I got the offer in TCS with very good offer. I wish good luck to TECHNOLOGICS finishing school Department & all the students studying there..

I did my mechanical design training and mechanical final year project here , I found it worth for time and quality training they provide.it was a wonderfull time i spent in Technologics instituteLess salary but good technical job placement

Placements