PGDAC

Post Graduate Training in Automation and Control Engineering

Course Description:

Today’s highly increasing competitiveness over the industry demands high quality and most consistent products with a competitive price. To address this challenge number of industries considering various new product designs and integrated manufacturing techniques in parallel with the use of automated devices.

Automation takes a step further mechanization that uses a particular machinery mechanism aided human operators for performing a task. Mechanization is the manual operation of a task using powered machinery that depends on human decision making.

One of the remarkable and influential moves for getting the solutions of above mentioned challenge is the industrial automation. Industrial Automation facilitates to increase the product quality, reliability and production rate while reducing production and design cost by adopting new, innovative and integrated technologies and services.

Course Objectives:

- Complete knowledge of Automation.

- Able to Program, Testing & Commissioning of Hardware.

- Able to Troubleshoot Hardware & Software.

- Able to work in Manufacturing, Production, Oil & Gas, Power Plant etc.

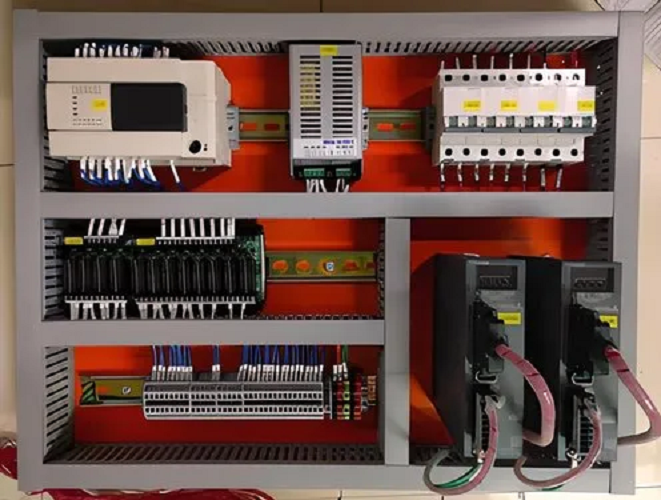

- Control & MCC Panel Wiring & Designing.

- Real-time Projects Execution.

The primary and overall objective of this course is to give a hands-on experience of PLC, SCADA, VFD, HMI, DCS, Field Instruments.

- Introduction about industrial automation

- History of industrial automation, Need of automations in industries

- Example for industrial automation

- Automation control circuit and power circuit

- Field Instruments, Types and working of field devices

- Automation using relays and field devices

- Examples for relays and field devices & Logical functions done by relays and field devices

- Introduction about Programmable Logic Controller, History of PLC, Architecture of PLC

- CPU, IO Modules, Power Supply and Communications, Input and Output Devices, Need of PLC for Industrial Automation

- Types of PLC Models, Introduction about PLC Programming

- Types of Programming Languages, Introduction about PLC Programming software

- Ladder logic diagram, Structure of program, Procedure for creating ladder diagram, Logical function done by ladder program in software.

- Interfacing the field component to PLC, Sink and Source type wiring, Need of push button for industrial automation

- Importance of latching and unlatching concepts, Memory concept

- Working with – All Major Brands of PLC

- Interlocking & Trip concept

- Types of interlocking, Need of interlocking

- Timers, Types of timers & Example Problem for automation using timers

- Need for counters & Types of counters – Example for automation using counters

- Jump and subroutine & Importance of loop instruction – Examples : Automation using Jump and Subroutine. – Upload and Download Program.

- Introduction, definition and history of Supervisory Control and Data Acquisition,

- Typical SCADA System Architecture, Communication Requirements,

- SCADA systems in operation and control of interconnected power system, Power System Automation, Petroleum Refining Process, Water Purification System, Chemical Plant

- Remote Terminal Unit (RTU), RTU Configuration, RTU Hardware Modules

- Project Creation in Display, Tags, Library, Run Time, Security, Working with Properties, Animation, Alarm Setup, Trend, Language Switching, Interfacing PLC to SCADA.

- Industrial Project Documents

- P&ID Diagrams & IO List Preparation

- VFD Selection, Functions of VFD Switches & Symbols,

- Operate motor using VFD Console switches.

- Parameterisation, Checking Load, rated Voltage & current

- Comissionining, No Load Test, Speed Modulation, ON/ OFF Command, Trip Status, PID Tuning

- Interfacing PLC To VFD, Real Time Interface to PLC SCADA

- Intro to HMI

- Designining In HMI- Diffrent Types of Operaters, Textual & Graphical

- Properties for Design, I/O Configuration, Wiring of HMI, Data Handling

- Configuration & Interfacing from PLC to PC

- DCS – Distributed Control System

- Architecture of DCS, Hardware Configuration , I/O Modules, Communication Module, Troubleshooting

- I/O Wirining, Programming, CPU IP Setting & Addressing, Node Addressing, Upload & Download Monitoring,

- SCADA Interfacing, Fault Detection, Operater Interface, Designing, OPC / ODBC

- Communication Protocol, Ethernet

- Projects, Assignments & Test

-

- Rated Best Training Facility In India:

-

Students Reviews

-

- Learn , Involve & Evolve